Tubular Heater Manufacturers

Hindon Electricals is one of the leading Indian Tubular Heater Manufacturers. The company manufactures a wide range of quality heating solutions for different Industries. Due to our excellence and innovation, we have established a strong reach in the market.

Our company boasts high technical expertise, vast resources, engagement, and more than three decades of experience. We consistently deliver quality. Customer satisfaction is our top priority. We guarantee timely delivery which is the ethics of high-standard products that the best companies around the world expect.

Delivery of quality is only possible with the help and support of dedicated professionals along with the modern infrastructure and qualitative inputs. Hindon Electricals makes a balance to perform an important role in different manufacturing industries.

About Our Tubular Heater

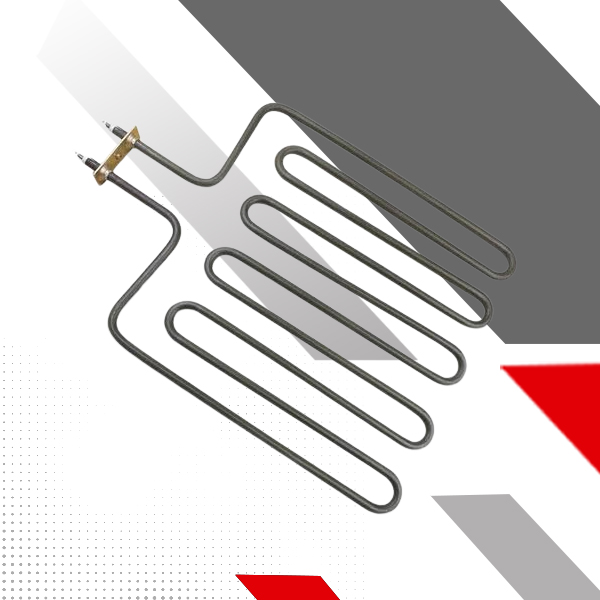

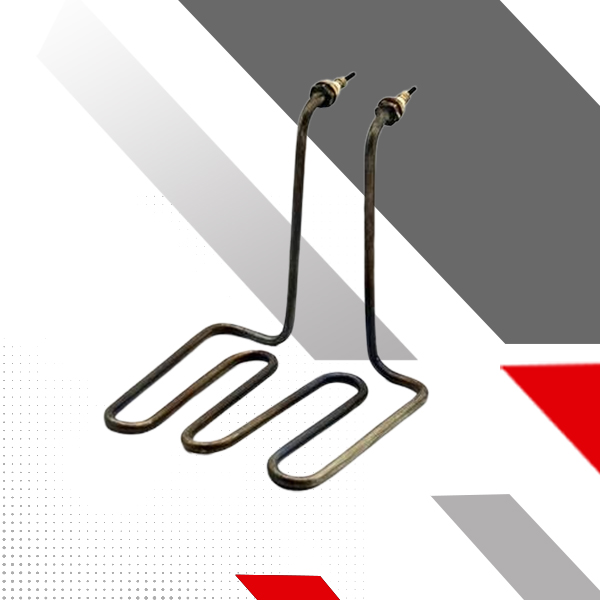

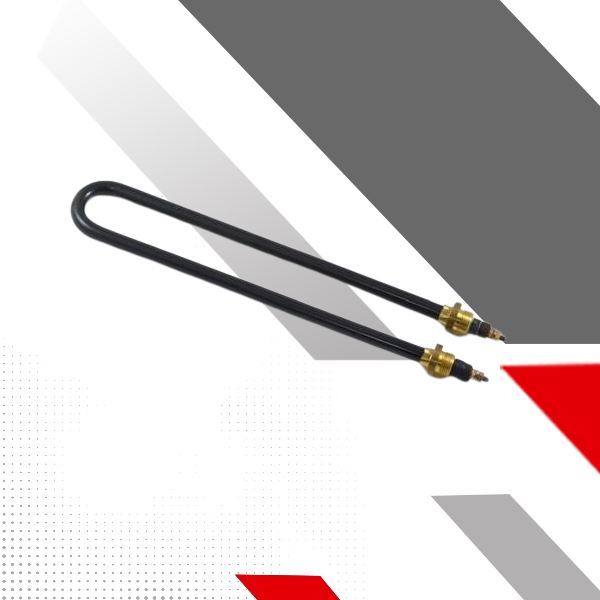

Our tubular heaters are sheathed units. They consist of a metal tube with a heating element inside enclosed with a resistance wire coil. These heaters are designed to transfer heat through conduction, convection, or radiation. They are extremely versatile and can be shaped into various configurations such as coiled, bent, straight, and other forms that fit different applications.

The main purpose of tubular heaters is to provide reliable, consistent, and efficient heating.

Benefits Of Our Tubular Heater

- Effective heat transfer

- High energy efficiency

- Provides equal heat distribution

- Tolerate high temperatures and harsh environments

- Excellent temperature control

- Suitable for heating air, liquids, and surfaces

- Minimal maintenance requirements

- Easy to install and manage

- Cost-saving due to no moving parts or requiring frequent cleaning

Our heaters are designed using superior insulation material including magnesium oxide. They contain several features such as high thermal conductivity and low electrical conductivity. Their robust construction can handle physical stress, vibration, thermal shock, and corrosion.

They are crafted from different sheath materials such as steel, stainless steel, Incoloy, or Inconel to withstand various chemicals, temperatures, and pressures. These heaters are connected to thermostats, controllers, or sensors that regulate the temperature and power output of the heater. Moreover, our tubular heaters can be modified with different electrical ratings, heater diameters, and heater lengths.

Industries and Applications

Hindon tubular heaters are widely used in various commercial, scientific, and industrial heating solutions for numerous applications. These include manufacturing, chemical, pharmaceutical, HVAC, automotive, plastic, textile, food and beverage, and more.

Our heaters control different applications such as ovens, water heaters, industrial baths, and space heaters. Tubular heaters are essential in processes requiring precise temperature control and uniform heat distribution, such as in manufacturing, food processing, and laboratory applications.

If you want to invest in the components to attain your industrial purposes, keep in contact with Hindon Electricals products. Being the most prominent Tubular Heater Manufacturers, we deliver sturdy and durable material crafted with premium raw components. Plus, our high-end and the latest technology meets the international industry standard.

Our offered range is highly tested and qualified to continually work at high temperatures with diverse applications. Besides these, you can receive excellent product delivery to your doorway within the promised time frame. Send us your queries regarding our offered products. Our experts help you invest in the best products.

- TECHNICAL SPECIFICATIONS

| Sheath Material | Copper, Steel, 304 Stainless steel, INCOLOY, Titanium Other alloys as per application selection |

|---|---|

| Watt Density. | Up To 120 W/in² Or 47 W/cm² |

| Sheath Length | Up To 10meter |

| Diameter | 6mm, 8mm, 11mm, 12.5, 13.7mm, 14.5mm, 16mm and 18mm |

| Element clamp | Customized |

| Mounting brackets | Customized |

| Termination Option | Single-ended and Double-ended design |

| End Seal Options | Teflon, Silicon Rubber, Epoxy, and Cement. |