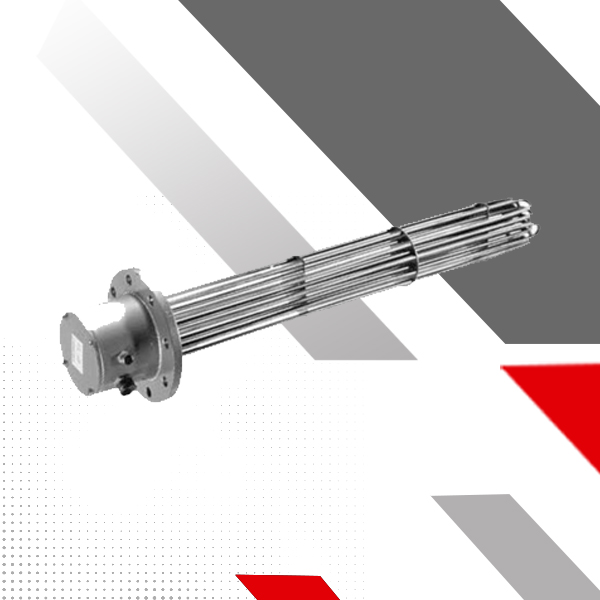

FLANGED IMMERSION HEATERS

Flanged industrial immersion heaters are amongst the most popular heaters owing to wide customization, easier installation and operations in stringent environment. Made by brazing or welding flange with several hairpin elements or bulge tubular elements, these are designed for heating chemical, petroleum and water based applications specially heat transfer fluids, medium and lightweight oils and water in tanks and pressure vessels. A thermocouple or RTD is often used within the bundle of elements to maintain the desired target temperature. Extra wiring boxes to make electrical connections are provided with it. Tubing known as a thermowell is used to protect thermocouples and heating elements. Different alloys and materials can be used to suit specific applications. For instance, steel flanges are used for deionized water, lubricant oils, heavy and light oils, waxes as well as mildly corrosive liquids and low flow gas and water tank heating. Stainless steel flanged heating elements are used with mild and severe corrosive solutions and military applications. The sheath materials used can be steel, stainless steel, copper as well as exotic alloys such as incoloy.

Different sheath materials used have different operating temperatures and watt densities. While selecting the material these values must match your criteria. Table shown below will help to make an ideal selection.

- TECHNICAL SPECIFICATIONS

| Sheath Material | Maximum operating temperatures | Maximum Watt | |

|---|---|---|---|

| °F | °C | W/in² | |

| INCOLOY | 1600 | 870 | 100 |

| 304 stainless steel | 1200 | 650 | 100 |

| Steel | 750 | 400 | 30 |