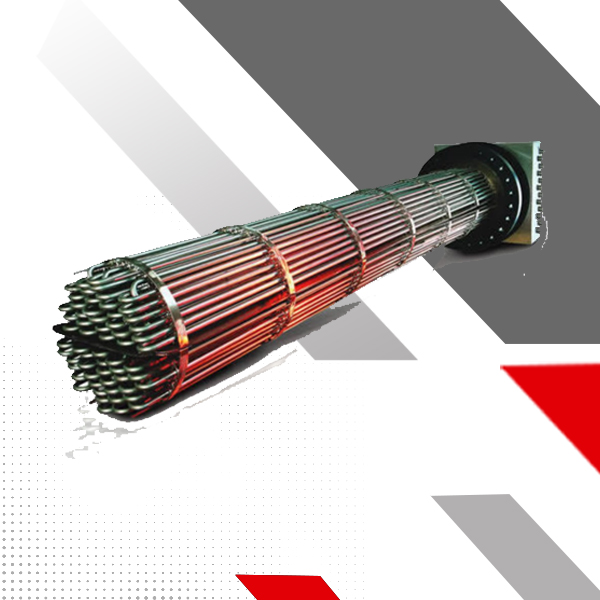

CIRCULATION HEATERS

Circulation heater (a.k.a inline heaters) is basically an immersion heater covered by an anti-corrosion metallic vessel chamber. It is accompanied by National Pipe Thread (NPT) screw plug or ANSI flange heater assemblies mated with a pressure vessel. The vessel is mainly used to provide insulation to prevent heat loss in the circulation system. An inlet flange transports the fluid into the circulation system, which is then circulated and heated until the desired temperature is reached. The heating medium will then flow out of the output flange at a fixed flow rate decided by the temperature control mechanism. Since it is a compact heating system, the operation is fast and executed in a short time. The heat generated is evenly distributed and the efficiency of the heater is high. Drain valves are also provided to remove leftover fluids or residues. Temperature sensors can be used with any control to achieve the desired temperature range. To manage the liquid flow rate of the heater, the wattage can be manipulated. When the requirement is such that liquid is to be pumped around anyway, a circulation heater is a logical choice.

- TECHNICAL SPECIFICATIONS

| Sheath Material | Maximum operating temperatures | Maximum Watt | ||

|---|---|---|---|---|

| °F | °C | W/in² | W/cm² | |

| INCOLOY | 1600 | 870 | 120 | 18.6 |

| 316 stainless steel | 1200 | 650 | 120 | 18.6 |

| Steel | 750 | 400 | 120 | 18.6 |