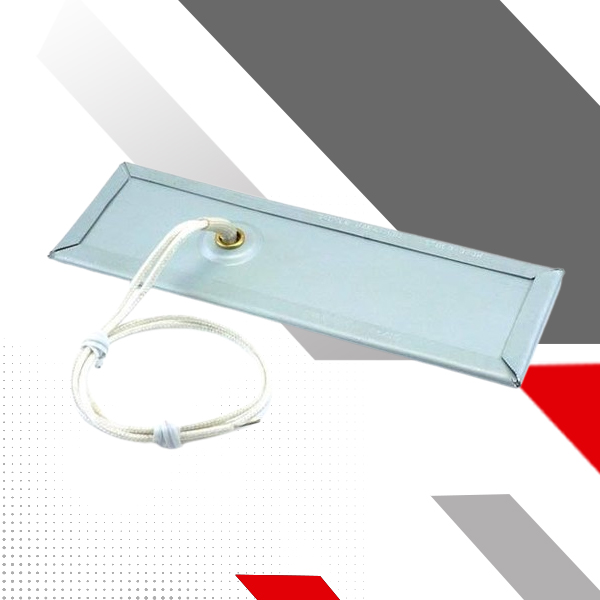

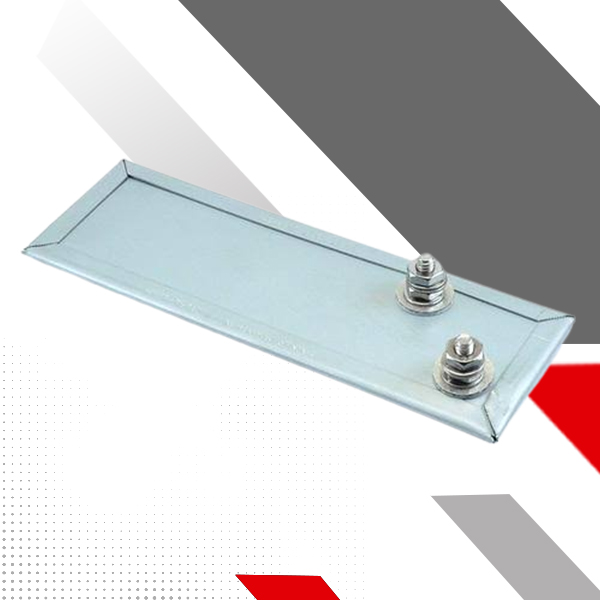

MICA STRIP HEATERS

Strip heaters, commonly known as component or clamp heaters, based on the principle of convection air heating, uses surface area to transfer heat effectively. Using most advanced heat technologies, strip heaters are an outstanding industrial heating product. It comprises of a heating element, a protective sleeve or sheath, and mounting hardware and can be clamped or bolted onto objects or solid surfaces. A coiled nickel chromium element wire is placed in the center of the heater. The element wire is then embedded in magnesium oxide (MgO) based insulation and compacted into a solid mass creating excellent heat conductivity and high dielectric strength. The heater is then enclosed in desired sheathing. Temperature can be controlled by using a temperature controller such as a thermostat. When using strip heaters, proper sheath material for resisting rusting or oxidation and suitable watt density of the element should be selected keeping application. They can be shaped and sized according to the requirement. A moderately inexpensive way of heating, strip heater is a tremendous solution to meet any budget.

- APPLICATIONS

- TECHNICAL SPECIFICATIONS

- Blow Molding

- Food warming

- Heating rubber platen

- Packaging and sealing

- Compression molding

- Laboratory equipment

- Heating inks

- Hot Plates and ovens

- Sealing bars

| Sheath Material | Iron, Steel, 304 Stainless steel, Aluminum, Zinc coated steel |

|---|---|

| Watt Density | Up to 45 W/in² |

| Voltage | 480V |

| Watt Density | Up to 45 W/in² |

| Operating temperature | Upto 650°C |

| Length | 5½ to 48 inches |

| Width | 1 ½ inch |

| Operating temperature | 650°C |