RTD ( RESISTANCE TEMPERATURE DETECTOR )

Resistance Temperature Detectors (RTDs) are temperature sensors composed of certain metallic elements whose change in resistance is a function of temperature. As the name implies, these are sensors used to measure temperature by correlating the resistance of the RTD element with temperature. A small current is passed through pure electrical wire and voltage which is proportional to resistance, is measured and converted to units of temperature. Manufactured by winding a wire (wire wound elements) or plating a film (thin film elements) on a ceramic or glass core, it is sealed within a ceramic or glass capsule. RTDs offer a wide temperature range (-50 to 500°C for thin-film and -200 to 850°C for wire-wound), so selecting the proper element and protecting sheath material is important for functionality. Excellent degree of repeatability, stability and accuracy has made RTDs a common name in laboratory and industrial processes. Resistance to oxidation and corrosion can be achieved by using metals such as platinum, while other elements such as copper, nickel and nickel-iron alloy are not so popular due to lower temperature capabilities and instability. RTDs are relatively immune to electrical noise and therefore well suited for temperature measurement in industrial environments, especially around motors, generators and other high voltage equipment. Available in various configurations for specific applications, some varieties of thermocouple are:

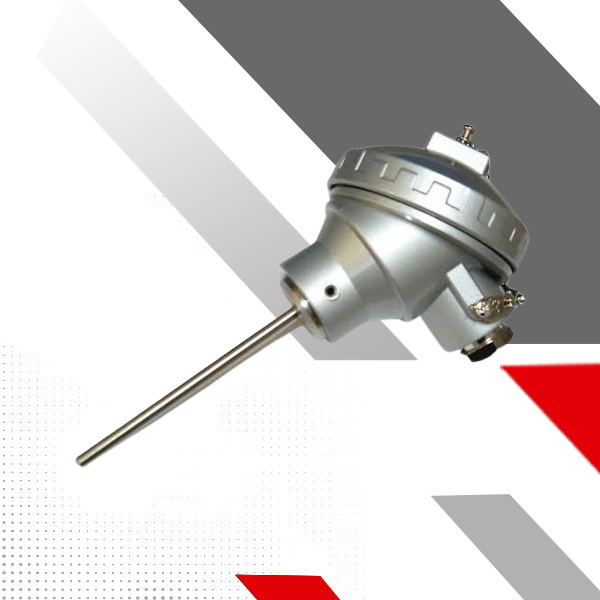

RTD with thermowell

- Mineral insulated RTD

- Special RTD

A choice between RTD and thermocouple must be made keeping in mind some factors such as

- Temperature Range

- Response time

- Size

- Accuracy and stability requirements