High Density Cartridge Heater

Hindon Electricals is one of the prominent High density cartridge heater manufacturers in India. The company focuses on quality and innovation and continuously delivers innovative solutions. Our experts develop a large variety of heating elements that meet the needs of various industries.

Our High Density Cartridge Heater is mainly utilized in particular industrial heating processes. They directly heat the material in narrow spaces. Their compact size and high watt density enable quick heating times and actual energy use.

About Our High-Density Cartridge Heater

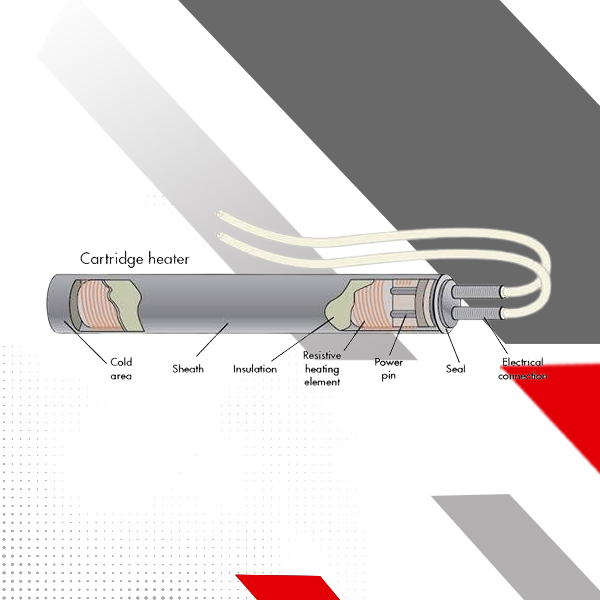

Our High Density Cartridge Heaters come in a compact cylindrical pack. Their concentrated powerful punch can extremely improve your industrial heating processes. These heaters consist of a cylindrical stainless steel or Incoloy sheath along with a high-watt density resistance coil. The coil is compressed with magnesium oxide powder to enhance thermal conductivity and insulation.

The High Density Cartridge Heaters designed by Hindon Electricals contain features, such as uniform heat distribution, exclusive heat in compact form, high-temperature capabilities, robust construction material such as stainless steel and INCOLOY, and resistance to high-temperature extremes up to up to 760°C (1400° F).

Plus, the watt density is up to 400 W/in², voltage capacity is up to 480V AC. Besides these, heaters tolerate high pressure and are protected from corrosion from moisture and various industrial conditions.

Benefits Of Our High-Density Cartridge Heater

- Provide consistent heat in small-size

- Excellent heat distribution provides controlled processes and high-quality end products

- Quick heating response time increases production capacity

- Direct heat transfer reduces energy waste

- Long-lasting performance in harsh conditions

- Minimal downtime reduces energy consumption and operational costs over time.

- A single heating solution covers multiple processes

- Enables installation in confined space

- Excellent safety reduces accidents related to uneven heating

Industries And Applications

Our heaters are commonly employed in various industries such as plastic processing, the packaging industry, food processing, the healthcare sector, and more.

They attain various applications including semiconductor chamber heating, die bonding, freeze protection, humidity control, sterilizing medical devices, metal die casting, seal bars, high-temperature glass forming equipment, equipment dicing in cold climates, and many other applications that work under even heat.

Their excellent functions result in perfect plastic parts, keep food packaging sealed tight, and keep the medical equipment free from bacteria. Plus, our heaters are customizable. We can design them according to your required size, wattage, and material.

Our Quality Assurance

Being one of the leading manufacturers, we have utilized supreme quality raw components and the latest possible technology. Our experts develop the product to meet international quality standards.

Our focus is to deliver out-of-the-box products that comply with the demands of our customers. We conduct strict quality control processes, including testing for heat distribution, temperature stability, and durability under high-stress conditions. Moreover, we also ensure compliance with industry standards and certifications to guarantee product reliability and safety. Thus, we ultimately maintain customer trust and satisfaction.

If you are looking for a High Density Cartridge Heater, you can trust Hindon Electricals. We are happy to serve you to your satisfaction. Contact our experts for detailed information about the product.

- APPLICATIONS

- TECHNICAL SPECIFICATIONS

- Semiconductor chamber heating.

- Semiconductor wire and die bonding.

- Freeze protection and deicing of equipment in cold climates or applications.

- Humidity control.

- Patient comfort heating used in medical devices.

- Metal die casting.

- Seal bars used in packaging equipment.

- High-temperature glass forming equipment.

| Sheath Material | Stainless steel, INCOLOY |

|---|---|

| Watt Density | Up to 400 W/in² |

| Design temperatures | Up to 760°C (1400° F). |

| Voltage | Up to 480V AC |

| Length | Up to 72 inches |

| Leads | Stranded/ Swaged in/ Pin leads/ Crimped on/ Customized |

| Controls | Thermocouple/ RTD |

| Sheath Length tolerance | +3% (standard), special tolerance available on request |

| Wattage length | +5%, -10% |

| Resistance tolerance | +10%,-5% |