Cartridge Heater Manufacturers

Hindon Electrical is one the prominent Cartridge Heater Manufacturers known to deliver exceptional quality and performance. We manufacture, distribute and export cartridge heater to various industries. Following a customer centric approach, we cater to diverse client needs by focusing on quality and innovation.

Our cartridge heaters are used in many industries for efficient localized heating. They have high watt density which allows quick heating in narrow spaces and is safe to use.

About Our Cartridge Heater

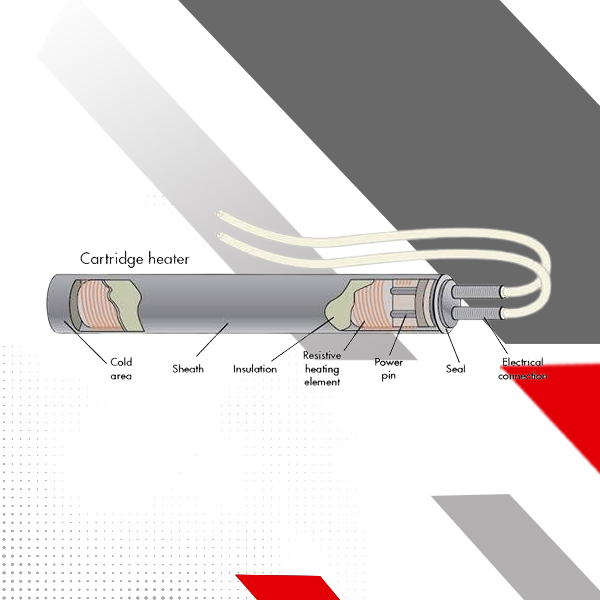

We provide cartridge heaters in cylindrical form and insulated wire for electrical supply. Heat generated by cartridge heater is concentrated and targeted to specific spaces and uses electrical supply for heat generation. Here are principle and construction process of our cartridge heater:

- Working Principle: The principle used in heating by cartridge heater is Joule Heating Principle, in which electrical energy is converted into heat energy using highly conductive metal coils.

- Construction: The cartridge heater contains heating coil of nickel-chromium alloy, metal sheath of stainless steel or incoloy, and both are separated by insulation layer of magnesium oxide to prevent current from flowing into sheath. The coil is connected to insulated wires for electrical supply.

- Watt Density: It is a critical factor to assess the heat generation capacity per unit area of coil. Our cartridge heater has high watt density which is up to Up to 400 Watt per square inch.

Benefits of Our Cartridge Heater

● Targeted and controlled heating in small, confined and sometimes unreachable spaces

● Excellent heat distribution capability

● Energy efficient heating which also saves time

● Highly durable while providing great performance

● Robust design to avoid downtime due to malfunction, saving operational costs

● Safe to use in tricky places as well

Industries Which Use Our Cartridge Heater

Our cartridge heaters have many user across diverse industries, which includes plastic molding, medical equipment, food processing, aviation system, marine system, packaging industry and many other industries which use sensitive manufacturing processes.

These heaters play a vital role in various manufacturing processes, including heating semiconductor chambers, plastic bonding, die bonding, freeze protection, sterilizing medical devices, metal die casting, sealing bars, high-temperature glass forming, and equipment dicing in cold environments and many other processes requiring uniform heat distribution.

Their exceptional performance ensures flawless plastic components, securely sealed food packaging, and contamination-free medical equipment. Additionally, our heaters are fully customizable to meet your specific needs, allowing for tailored designs in terms of size, wattage, and materials.

Why Choose Our Cartridge Heater

As a leading manufacturer of cartridge heater, we set quality benchmark in designing, engineering and production of each product. We procure best quality raw materials from trusted vendors and use state-of-the-art technology in fabrication process. We have expert team of engineers and operators who are always dedicated to meet international quality standards and push themselves to fulfil the scope of improvement.

With commitment to sustainability, we ensure efficient power usage and minimum material wastage. Not only that, we ensure our quality isn’t compromised therefore we conduct stringent quality tests which results in high durability and performance of cartridge heaters.

Trust Hindon Electricals for your targeted heating requirements in narrow spaces, and we will serve you with best product in promised delivery time for your ultimate satisfaction. Contact our experts for detailed information about the product.

- APPLICATIONS

- TECHNICAL SPECIFICATIONS

- Semiconductor chamber heating.

- Semiconductor wire and die bonding.

- Freeze protection and deicing of equipment in cold climates or applications.

- Humidity control.

- Patient comfort heating used in medical devices.

- Metal die casting.

- Seal bars used in packaging equipment.

- High-temperature glass forming equipment.

| Sheath Material | Stainless steel, INCOLOY |

|---|---|

| Watt Density | Up to 400 W/in² |

| Design temperatures | Up to 760°C (1400° F). |

| Voltage | Up to 480V AC |

| Length | Up to 72 inches |

| Leads | Stranded/ Swaged in/ Pin leads/ Crimped on/ Customized |

| Controls | Thermocouple/ RTD |

| Sheath Length tolerance | +3% (standard), special tolerance available on request |

| Wattage length | +5%, -10% |

| Resistance tolerance | +10%,-5% |